Unexplained Mystery of Ulfberht Viking Sword

The Ulfberht sword deserves to be put alongside the names of the most famous, and in this case mysterious, swords ever found. An enigmatic blade made by the Vikings and engraved with the word Ulfberht has stumped archaeologists. The sword is forged in such a way that it looks to have been made by technologies that weren’t available until 800 years after the Viking era.

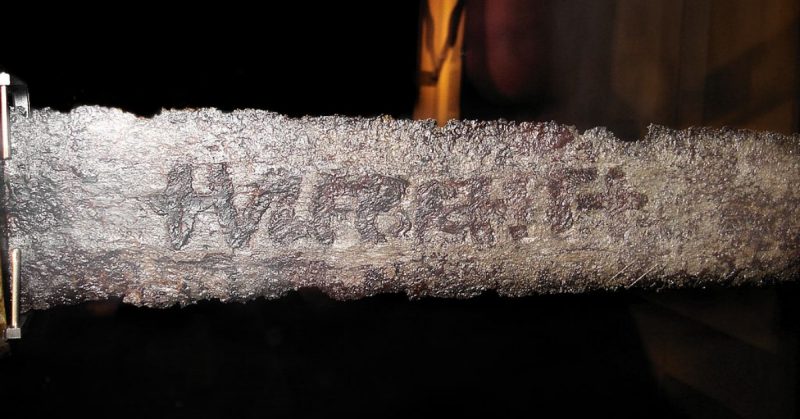

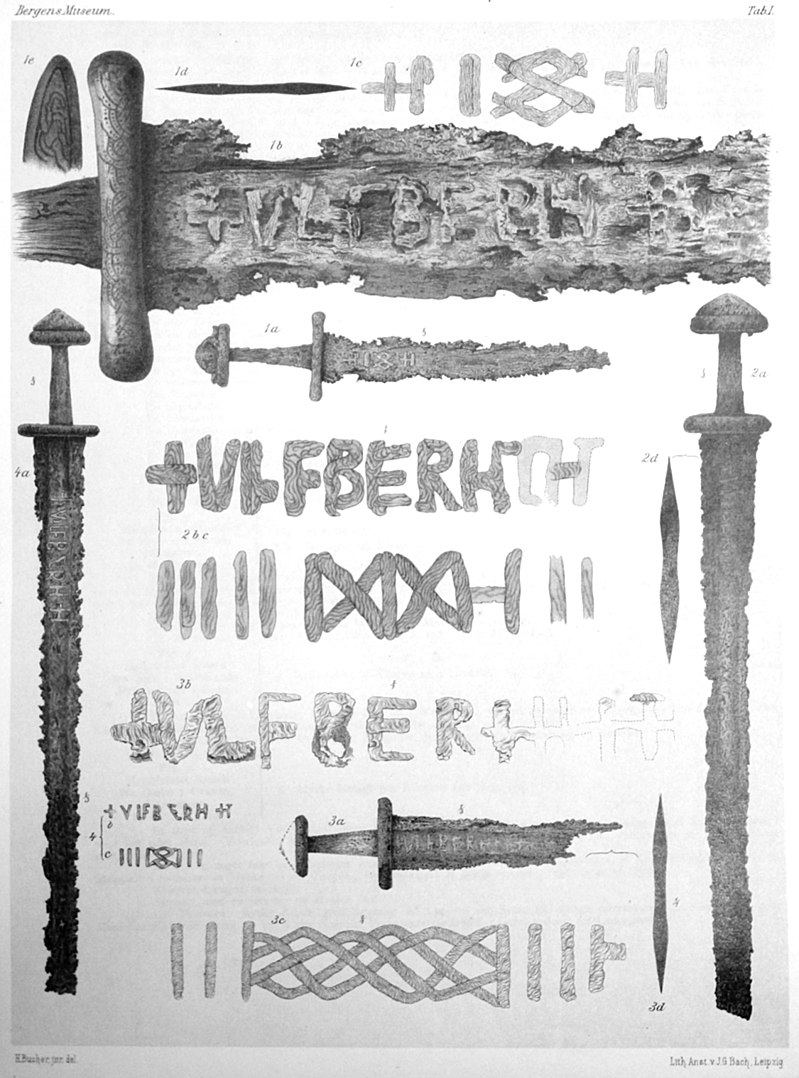

Ulfberht: unique swords with the inscription +VLFBERHT+ on the blade, dated between the 9th and 11th centuries. In the Viking Age, the privilege of having such a sword belonged exclusively to the elite, because an Ulfberht sword’s unmatched strength could only be had at a high cost. The sharpness and durability of the blade made it possible to cut through bone or a lower-quality weapon with one blow.

Around 170 of the swords have been found, all of which date from between 800AD to 1000AD, but the technology that would have forged them is from the Industrial Revolution of the 1800s and 1900s. These swords were said to have been sharper, stronger, and more flexible than anyone else’s. That gave the user a huge advantage in battle. You could block an enemy’s sword and trust that your blade wouldn’t shatter, which was a constant concern. And in an era where the best warriors wore mail coats, an Ulfberht sword would slice through that protection better than other swords.

It was the closest thing to a lightsaber in medieval Europe. And that’s actually a better comparison than you might think. That’s because the process used to make Ulfberht swords was centuries ahead of the competition. In fact, it wouldn’t be possible to replicate it on a large scale until the industrial revolution.

Before the discovery of the Ulfberhts, it was believed that the technology for hardening metal to such an extent originated during the Industrial Revolution. To do this, it is necessary to heat the metal to a temperature of 1,600° C. This indicates that the creators of Ulfberhts were about 800 years ahead of the Industrial Revolution with their methods for heating the metal to make the swords.

The inscription on the sword is located in the upper third of the dale of the sword, and is generally about 4.7-5.5 inches long. According to Lehmann, the sword contained a large amount of manganese, which refutes the version about raw materials being forged in the East. Garda was made from iron with a high arsenic content, indicating it’s a European feature. The handle of the sword was covered with a layer of lead and tin.

Lehmann determined that lead was mined in the Taunus region north of Frankfurt. One theory is that the sword was forged right near the place where its raw materials were extracted. In the Middle Ages, monasteries in the Taunus region participated in the manufacture of weapons.

Ulfberht swords’ grips differed in their outlines, but in most instances they were ornamented in an ethnically neutral geometric style such as with alternating strips of brass and red copper, supplemented with silver. These colored stripes gleamed, giving the sword a shimmering and precious appearance.

The secret to Ulfberht swords was the distribution of carbon in the blade. Steel swords were made by mixing iron and carbon to produce steel. Add too much carbon and the sword becomes brittle and breaks. Add too little, and it will just bend. The Ulfberht swords used the perfect amount to produce blades that were sharper and more durable than anyone else’s.

But we’re still not entirely sure how the makers did that, though it may have involved borrowing some the techniques used by Arab smiths to produce the famous “Damascus Steel.”

The process involved using trace amounts of other minerals and heating them together with iron and carbon in a crucible to produce first-rate steel. And getting these materials from as far as India involved a global trade network you don’t usually associate with the period.

Were the makers of the Ulfberht swords using the same techniques? Possibly. If not, then they somehow produced something very similar to Damascus Steel on their own, with almost no impurities in the metal. And they quickly became famous, and probably rich, for it.

Most likely, steel was shipped up from the Arab empires or India through the rivers of Eastern Europe by traders. There, they were turned into swords in what is now Germany. Then they were sold to Norse and Frankish nobles who wanted a quality blade to use against their enemies. It’s hard to say exactly what an Ulfberht cost, but it was probably something only the richest noblemen could afford.

There are about 170 true Ulfberht swords that have survived to the present day. They’re all in the traditional “Viking” style with a long, double-edged blade and a straight crossbar over the grip and all of them have the name “Ulfberht” stamped into the blade. Whoever was making the swords clearly understood the importance of branding.

But like any modern brand, the Ulfberht brand was quickly beset with imitators. Because Ulfberht swords were so famous, other people soon realized they could sell their swords for more by stamping the Ulfberht name on the blade, even if they didn’t use the same techniques. And since the people who bought these swords were relying on them for battle, this had deadly consequences.